In Casting a Mold Is Used Into Which __________

Main Differences Between Cast and Mold. Once the plaster has solidified remove the clay and finish drying the plaster mold in the oven.

Different Types Of Casting Processes Used In Manufacturing

With the wooden stick scrape the resin into the molds and dont hesitate to apply a second or subsequent layer of epoxy until the casting reaches your desired volume.

. It works best for small-volume manufacturing. The statistics show more than 61 of all metal castings are. The pattern a metal piece in the shape of the desired part is reused to form multiple shell molds.

Expendable mold casting is a method that utilizes single-use or temporary molds. Plaster Mold Casting works much like other castings processes where a heated liquid material is poured into a mold that contains a hollow cavity of the desired shape. Molten metal introduced into the mold is flung against the interior surface of the mold producing a casting that can be free of voids.

The molds can range from very cheap sand molds to elaborately machined chromium-steel molds costing well into the 6 figure range. After the rubber dries it can be cut into two pieces each piece resulting in a mold for one half of a resin piece. In order to avoid sanding between pours subsequent pours must be applied when the previous ones have cured to a tacky stage.

However in shell mold casting the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. It can be used to make metal components of all sizes ranging from 1kg to hundred tons. Cast is the final product that is obtained when the casting liquid is poured into the mold and is left to harden.

Open-faced molding is used when casting pieces where one side is flat like when making a glass tile or a coaster. Some are temporary and are destroyed during the casting process. These metal casting processes may be completed in a.

641 Permanent mould casting. Mold on the other hand is the hollow cavity that has been formed in order to imprint the object and take a replica out of it. These methods allow foundries to precisely control the rate at which a mold fills.

Others are permanent and are reused again and again. My understanding is that yes it can be done. Centrifugal casting is used to produce long cylindrical parts such as cast iron pipe by relying on the g-forces developed in a spinning mold.

Air or gas vacuums mechanical or centrifugal forces are all used in pressure casting. Vacuum casting is sometimes referred to as polyurethane casting or urethane casting as polyurethane resin a type of elastomer is used as the casting material. This object is called a model.

Shell mold casting is a metal casting process similar to sand casting in that molten metal is poured into an expendable mold. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Casting is a process in which a liquid is poured into a mold in order to produce a product.

Traditional metal casting techniques include lost-wax casting plaster mold casting die casting and sand casting to name a few. Then pour the liquid metal into this mold to create a casting partIt is one of the oldest casting processes. The glass industry blows.

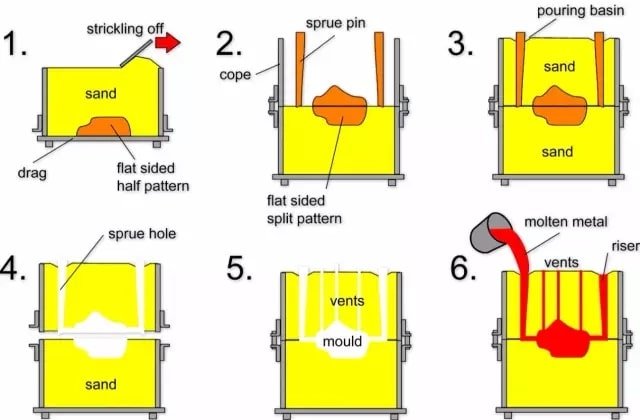

Molding is typically used for softer materials while casting is better suited for harder materials. Sand casting known as sand molding casting is a casting process that uses sand as a mold. Sand casting molds are molds used in metal casting that used once after pouring metal fluid and being broke to collect the casting.

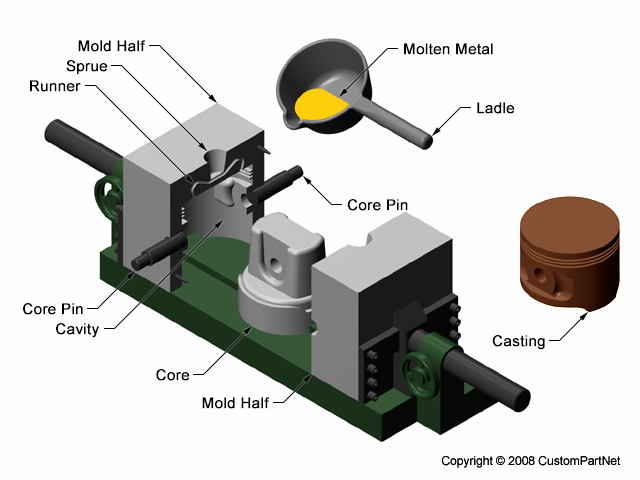

One of the key difference between molding and casting is the type of material that can be used. Casting is pouring molten liquid into a mold where it is subsequently allowed to cool solidify before ejection for use. Permanent mould casting is a process for producing a large number of castings using a single reusable mould.

Vacuum casting is an economical alternative to injection molding for making plastic components as the production. During metal casting molten metal is transferred from a crucible into a mold to create a positive metal cast object. Expendable mold processes uses an expendable mold which must be destroyed to remove casting.

This is used to create the mold that should be removed from it. We used H-13 steel and it lasted for 1000s of shots. Plastic factories use metal molds and different processes like injection molding rotational molding and blow molding to produce plastic parts.

Making your own expendable mold is an inexpensive and relatively fast process. The process of making a cast is known as a casting while the. Common materials that are used in casting include metals plastics and concrete.

- Made of metal or ceramic refractory material. - Ex sand plaster. Pop it out carefully Do not pull it if your resin stuck because you will rip your mold.

Permanent mold processes uses a permanent mold which can be used over and over to produce many castings. There are several types of molds that are used in the casting process. The process was well established in the Bronze Age beginning c.

Then fill the mold with glass and cast it in a kiln. The mold can be cast more than. To make the mold pour plaster around a clay pattern and let it set.

Commercial ceramic factories use plaster molds and slip liquid clay to produce bowls cups candlesticks figurines and more. Casting is used for producing parts to near-net ie. Gravity always works with the same force but man-made forces can be varied.

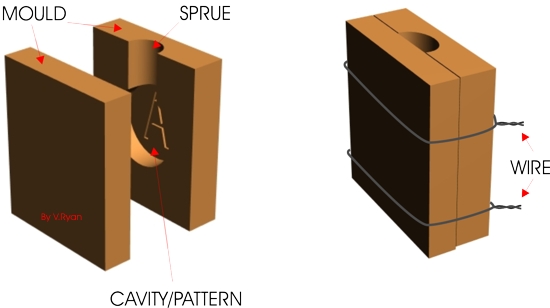

Casting involves making mold and pouring liquid material such as molten metal plastic rubber or fiberglass into the skin. A cast is a form created by this process. The casting process simply involves pouring molten metal into a mould where it cools and solidifies.

3000 bc when it was used to form most of the bronze pieces now found in museums. Many industries use mold making as a way of producing their wares. If you dont have the release agent simply soak the mold into some hot water which can effectively soften up the mold and resin.

Pressure casting methods use forces other than gravity to control the flow of metal into a permanent mold. The mould is then opened the casting removed and the mould is reused. Plaster mold casting also referred to as rubber plaster molding RPM is a method of pouring liquid metal into plaster molds which will produce aluminum or zinc castings.

The collected casting shaped in a sand mold features low precision poor surface finish and a large metal excess that would require post-machining. I have specified molds for diecasters-never used cast iron. Casting consists of pouring molten metal into a mold where it solidifies into the shape of the mold.

When creating a resin mold a three-dimensional 3D object is used to give shape to the mold. Complex resin molds are made by placing a model in a container and pouring clear rubber around the object. My further understanding is that cast iron is used so that the mold doesnt warp after the first time you pour molten aluminum into it.

Pour the composition into the molds. It is particularly valuable for the economical production of complex shapes ranging from mass-produced parts for automobiles. The artist produces many images to model the form usually clay wax or concrete.

Casting from long and skinny molds can be hard to get out try to use the mold release agent like detergent cooking oil and etc. Two categories of casting process. These molds are typically made from resin-bonded sand ceramic shell plaster investments or foam.

The metal and mold are cooled and the metal object is removed and finished.

Pattern Functions Casting Questions And Answers Sanfoundry

Mcq On Injection Mould Pdf Polymers Plastic

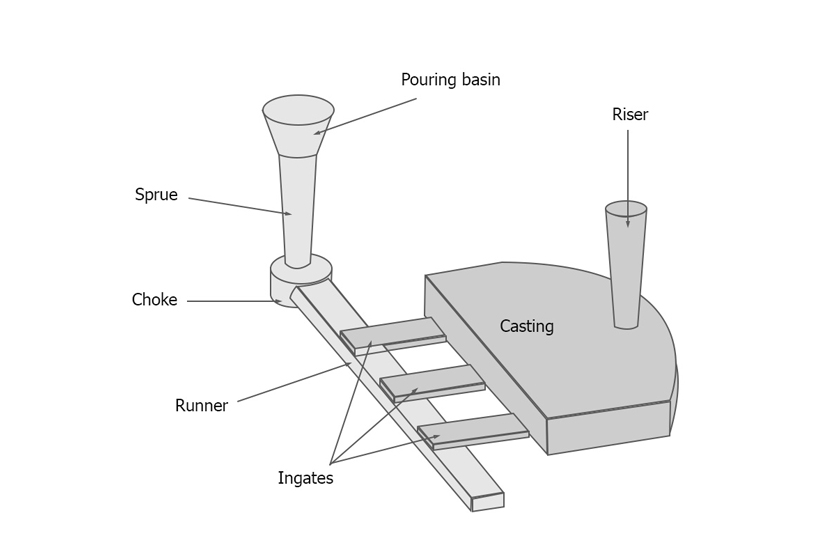

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Solved The Casting Produced By Forcing Molten Metal Under Pressure

Solved Which One Of The Following Casting Processes Produces The Pr

Shape Casting An Overview Sciencedirect Topics

Permanent Mold Casting An Overview Sciencedirect Topics

What Is Sand Casting And How Does It Work Metaltek

Solved Which One Of The Following Casting Processes Produces The Pr

Permanent Mold Casting An Overview Sciencedirect Topics

10 Different Types Of Casting Process Machinemfg

Comments

Post a Comment